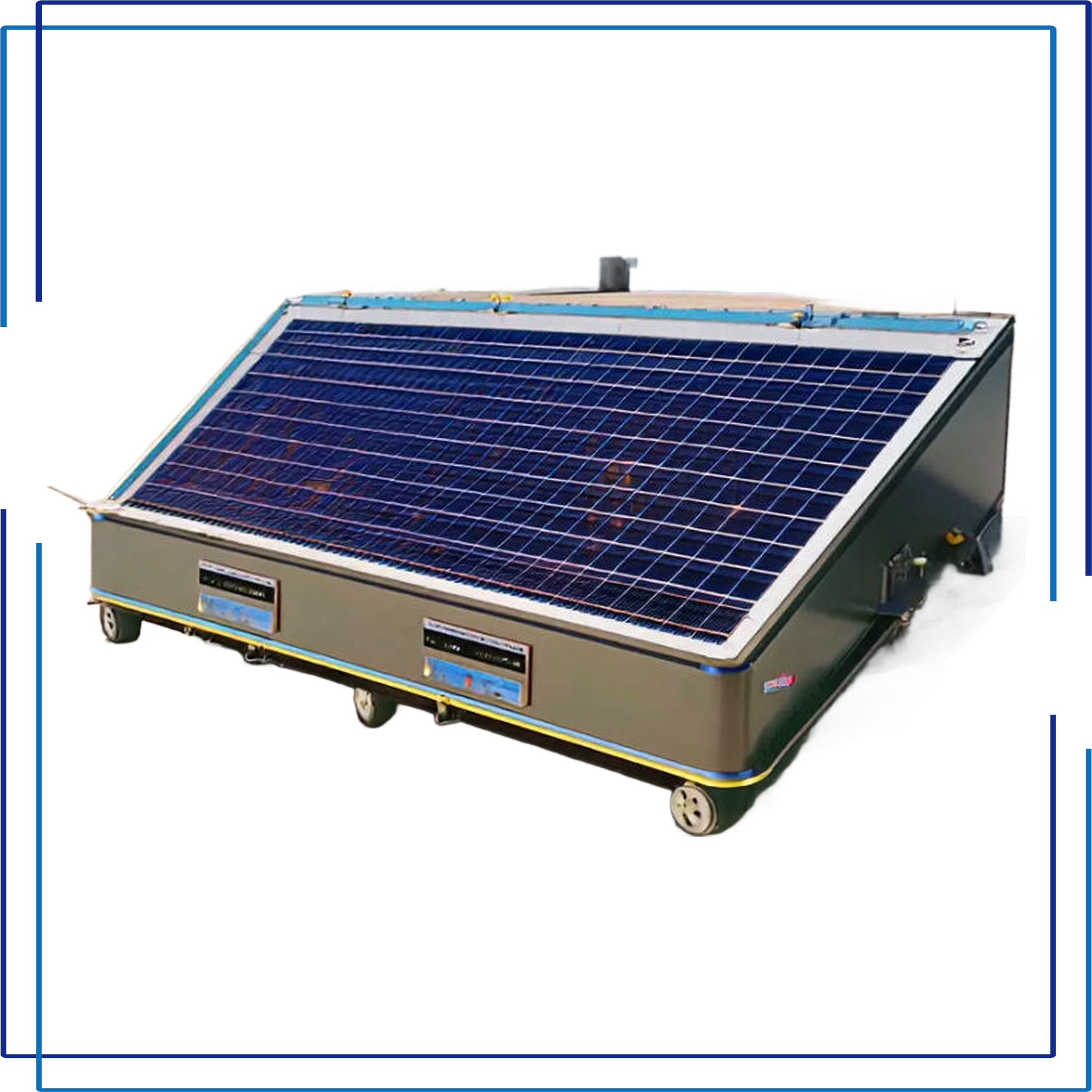

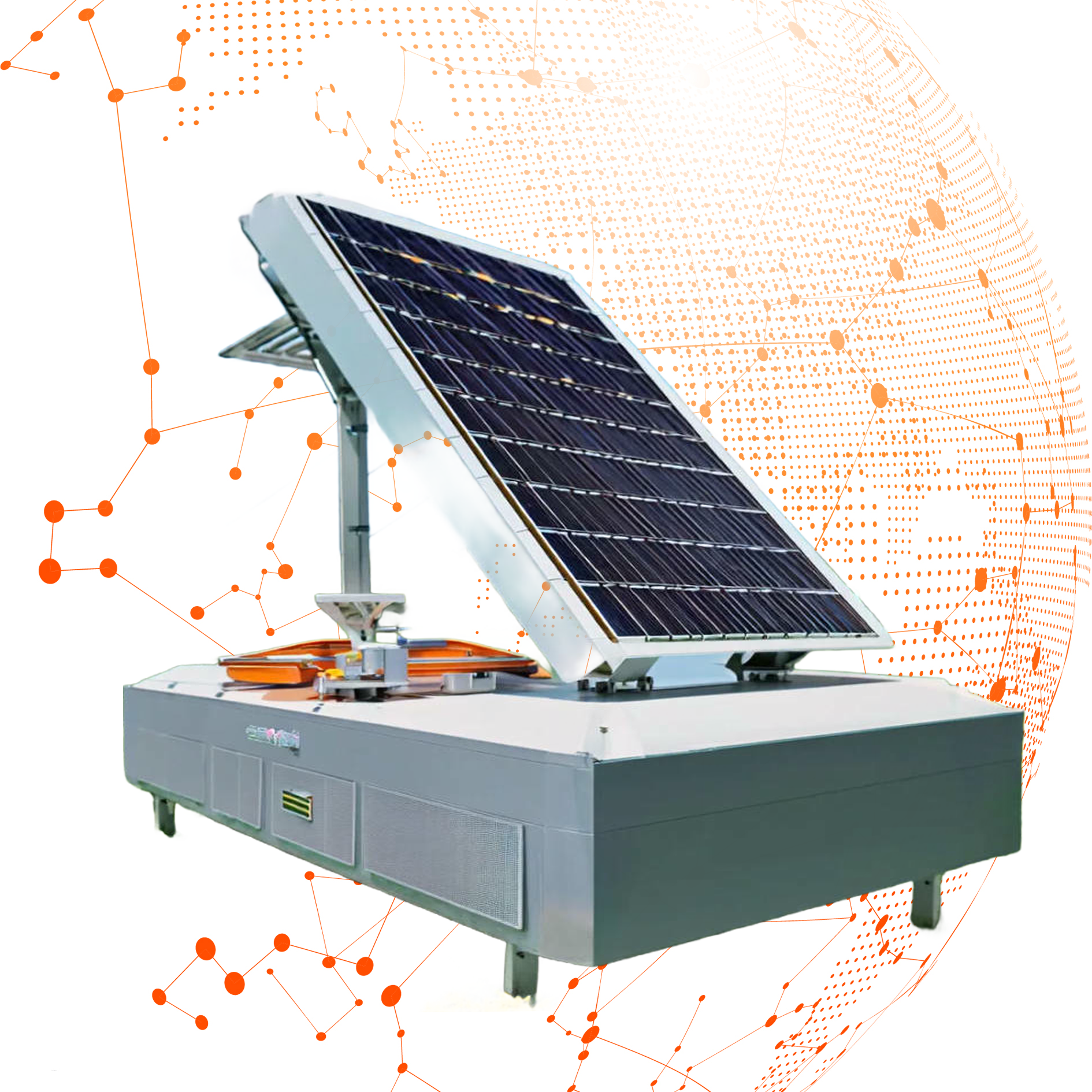

công ty năng lượng xanh

Tại công ty năng lượng xanh của chúng tôi, chúng tôi cam kết khai thác sức mạnh của các nguồn tài nguyên tái tạo để cung cấp các giải pháp năng lượng bền vững. Các chức năng chính của chúng tôi bao gồm phát triển, lắp đặt và bảo trì các hệ thống năng lượng xanh như tấm pin mặt trời, tuabin gió và thiết bị lưu trữ năng lượng. Các hệ thống này được trang bị các tính năng công nghệ tiên tiến như bộ biến tần thông minh và phần mềm giám sát thời gian thực giúp nâng cao hiệu quả và độ tin cậy. Các ứng dụng của chúng tôi trải rộng trên các lĩnh vực dân cư, thương mại và công nghiệp, cho phép khách hàng giảm thiểu dấu chân carbon và chi phí năng lượng. Với sự tập trung vào đổi mới và chất lượng, chúng tôi nỗ lực trao quyền cho các cộng đồng với năng lượng sạch, tái tạo.